Manufacturer And Exporter of Process Equipment And Measuring Instruments

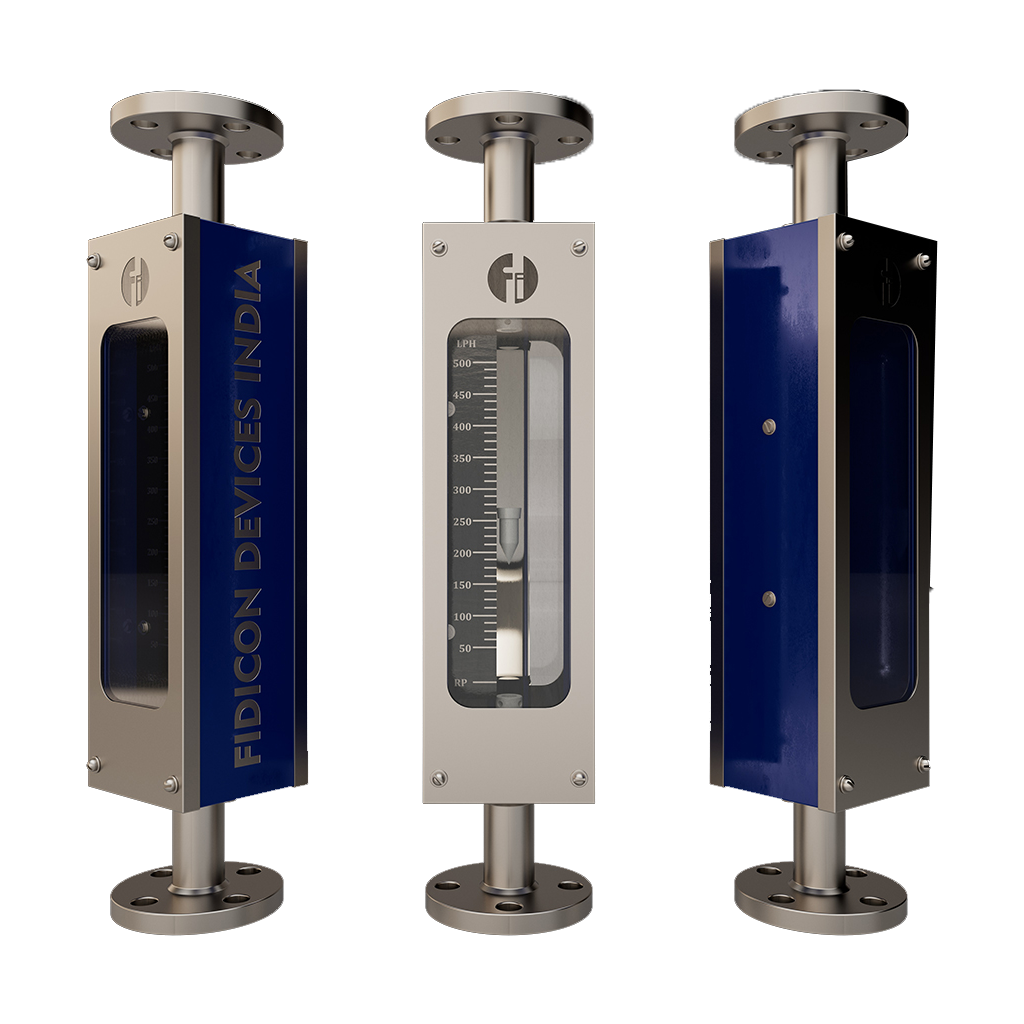

A glass tube rotameter is a type of flow meter used to measure the flow rate of liquids or gases in a pipeline. It consists of a glass tube with a float inside that is free to move up and down with the flow. The float is typically shaped like a cylinder or a ball, and is designed to have a higher density than the fluid being measured.

The flow rate can be determined by observing the position of the float inside the tube and referring to a calibration chart. The glass tube allows the operator to visually observe the float and the flow, making the rotameter a simple, low-cost, and reliable method of flow measurement.

The principle of operation of a glass tube rotameter is based on the relationship between the flow rate and the pressure drop across an orifice. The float inside the glass tube is positioned in such a way that it creates an obstruction, or orifice, in the flow stream. As the flow rate increases, the pressure drop across the orifice increases, causing the float to rise. Conversely, as the flow rate decreases, the pressure drop decreases, causing the float to fall.

The position of the float is proportional to the flow rate, and this relationship is calibrated on a chart. The chart is usually marked on the outside of the glass tube and displays the corresponding flow rate for a given float position. The rotameter is designed so that the pressure drop across the orifice and the consequent rise or fall of the float are proportional to the square root of the flow rate.

In summary, the glass tube rotameter works by measuring the pressure drop across an orifice created by the float and using this pressure drop to determine the flow rate. The position of the float inside the glass tube indicates the flow rate, and the operator can read this flow rate from the calibrated chart.

| Size : | 15NB TO 150NB |

| Connection : | THREADED, FLANGED (ANSI/ASA/ASME B16.5/PN/NPT) |

| Materials : | ASTM A216 GR. WCB(CS), SS 316, SS 304, PTFE, SS BUFFED, MS POWDER COATED, SS 316TI, HASTELLOY C, FRP, BOROSILICATE TOUGHENED GLASS, RUBBER, NEOPRENE RUBBER, METALLIC SPIRAL WOUND, CAF, FEP and other as per customer requirement. |

| Flow range | 10 to 20,000 LPH of water |

| Accuracy | ±1.5 % full scale reading |

| Glass Tube Rotameter Accessories | Screwed /Flanged |

| House -connection | |

| Face-To-Face Distance : | 500 mm |

This Variable Area Flow Meter is essentially a Glass Tube Rotameter.

The flow rate is measured as a function of the annulus area, and the differential pressure across the annulus region is constant. This location is shown as being in the position of a "Float."

| Glass Tube Rotameter Designed on variable area basis using tappered borosilicate glass tube pressure rating at 10kg/cm2 temp at 150°C. We are leading manufacturer & supplier of Glass Tube Rotameter in Gujarat, India. | |

| Material of wetted part | C.S./S.S..304/ S.S.316 PP/PVC/Teflon |

| Line Size | 15mm NB to 100NB |

| Flow range | 10 to 20,000 LPH of water |

| Accuracy | ±1.5 % full scale reading |

| Glass Tube Rotameter Accessories | Screwed /Flanged House -connection |

| Glass Tube Rotameter is

basically a Variable Area Flow Meter. The differential pressure across the annulus area is constant and the flow rate is measured as a function of the annulus area. This area is displayed as the position of a “Float”. |

||

| • | Various Material of Construction | |

| • | Line Size from 15 NB to 100 NB | |

| • | Heavy Duty Design with Maximum Visibility | |

| • | Ranges between 2.0 LPH to 25000 LPH | |

| • | Two Tone Powder Coated Excellent Finish | |

| • | No Threads in Body, Avoids Corrosion | |

| • | Face-To-Face Distance : 500 mm | |

| • | Single Piece (jointless) PTFE / PP claded end connections | |

| • | Easy to Maintain and Replace | |

| • | Suitable for on Line Installation | |

| • | Measuring Span : 1:10 | |

| • | Glass : Borosilicate | |

| • | Linear Scale | |

| • | Slip on Flange - facilitates change in line of sight | |

| • | Accuracy : +/- 2% of Full Scale | |

| • | SS | |

| Oil and gas pumping and refining processes | ||

| Fuel cell research | ||

| Chemical manufacturing | ||

| Analytical instrumentation | ||

| Water treatment and distribution systems | ||

| Industrial processes | ||

| Pharmaceutical productio |

SN |

Parts | OPTIONS | ||

A |

Enclosure |

MS- Powder Coated | SS- Powder Coated | SS- Buffed |

B |

Flange - NB | 15, 25, 40, 50, 80 | ||

C |

Flange Specifications | ASA-150, BS10-T-E, BS10 T-F, Din-10 | ||

D |

MOC Wetted | CS, SS304, SS316, CS-PTFE, CS-PP | ||

E |

Float - MOC | SS316, PTFE, PVC, Aluminium | ||

F |

Flange - MOC | CS, SS304, SS316 | ||

G |

PTFE Enve. Gland Packing | Nitrite , Silicon, Viton | ||

H |

Measuring Range in LPH of H2O @ T :- Ambt / Pr : - Atm | |||

Glass Size |

With

PTFE Float LPH |

With

SS 316 Float LPH |

Max.

Pressure Drop in mmwc |

Test Pressure |

PN

1 |

2-20 |

3-30 |

140 |

15 |

PN

2 |

3-30 |

6-60 |

||

PN

3 |

4-40 |

10-100 |

||

PN

4 |

6-60 |

20-200 |

350 |

15 |

PN

5 |

8-80 |

30-300 |

||

PN

6 |

12-120 |

40-400 |

||

PN

7 |

18-180 |

60-600 |

||

PN

8 |

20-200 |

80-800 |

600 |

12 |

PN

9 |

40-400 |

100-1000 |

||

PN

10 |

50-500 |

150-1500 |

||

PN

11 |

80-800 |

250-2500 |

||

PN

12 |

90-900 |

300-3000 |

900 |

9 |

PN

13 |

100-1000 |

350-3500 |

||

PN

14 |

150-1500 |

400-4000 |

||

PN

15 |

200-2000 |

600-6000 |

900 |

7 |

PN

16 |

250-2500 |

700-7000 |

||

PN

17 |

400-4000 |

1000-10000 |

||

PN

18 |

500-5000 |

1500-15000 |

900 |

5 |

PN

19 |

600-6000 |

2000-20000 |

||

PN

20 |

800-8000 |

2500-25000 |

||